Gujarat Hazardwest Management Co.

Gujarat Hazardwest Management Co.

Our heavy-duty JCB machinery ensures efficient earth-moving and construction operations with maximum productivity and reliability.

We provide fast and reliable forklift services — from excavation to earthmoving, ensuring safe and efficient material handling every time.

Durable and high-capacity storage tanks suitable for storing various liquids in industrial environments. Engineered with corrosion-resistant materials and integrated safety features. Customizable to suit different capacities and operational requirements.

Industrial-grade reactor tanks equipped with precise mixing and temperature control for chemical processing applications.

Designed for high-efficiency chemical reactions with uniform heat distribution.

Robust construction using stainless steel for corrosion resistance and durability.

Advanced agitation systems ensure consistent mixing of liquids, gases, or solids.

Custom pressure and vacuum configurations available for versatile operations.

At Gujarat Hazardous Waste Management Co., safety is the foundation of every operation we undertake. We follow a comprehensive and scientifically designed safety process to ensure the secure handling, transportation, storage, and disposal of hazardous waste. Each type of waste is first identified and classified based on its physical and chemical properties to ensure proper segregation and treatment. Our trained personnel, equipped with essential Personal Protective Equipment (PPE), handle waste with utmost caution, using standardized procedures to avoid spills, contamination, or accidents. During transportation, GPS-enabled vehicles with emergency response kits and trained drivers ensure waste reaches treatment facilities safely and securely. Once received, waste is stored in secure and controlled environments equipped with fire protection systems, gas leak detectors, and regular inspection routines. Scientific treatment and disposal methods are used in compliance with CPCB and GPCB guidelines, with real-time pollution monitoring systems to ensure environmental protection. In addition, we maintain high levels of emergency preparedness through regular drills, dedicated control rooms, and coordination with local emergency services. Continuous employee training and third-party audits further reinforce our commitment to operational safety, legal compliance, and zero-incident performance. At every stage, we strive to uphold the highest standards of safety, health, and environmental responsibility.

We believe that prevention is better than cure, and our systems reflect that principle. Every member of our team is empowered to act responsibly and safely. Our processes are reviewed and updated regularly in line with global best practices. With safety as our core value, we protect not only our workers and communities but also the future of our environment.

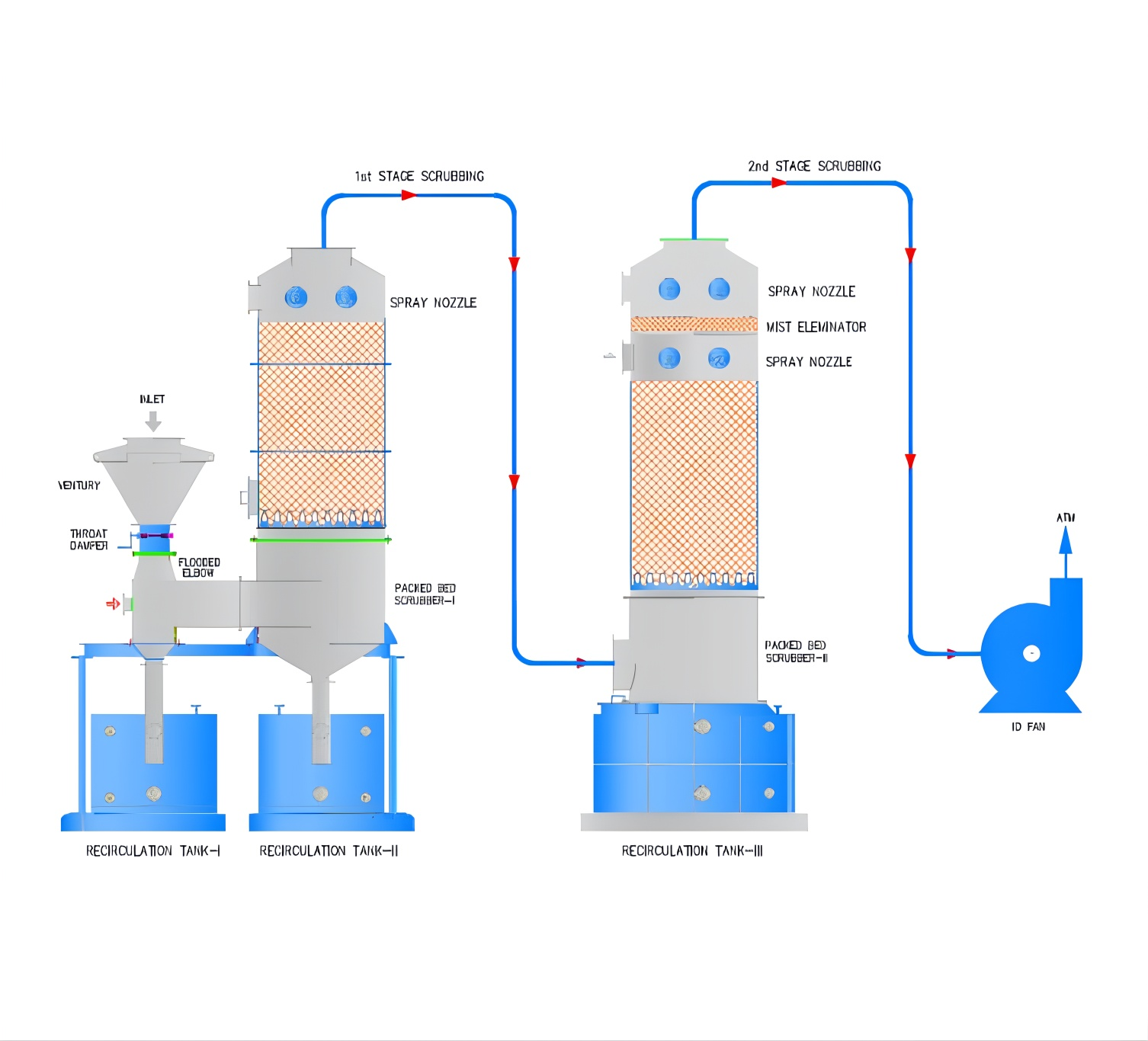

This industrial gas scrubbing system is a two-stage air pollution control unit designed to effectively remove harmful gases and particulates from process emissions. It features a Venturi inlet for initial gas-liquid contact, followed by two packed bed scrubbers equipped with spray nozzles and recirculation tanks to enhance the absorption of pollutants. The second stage includes a mist eliminator to capture fine droplets before the clean air is released through an induced draft (ID) fan. Constructed with corrosion-resistant materials, the system ensures efficient performance, regulatory compliance, and long-term durability in demanding industrial environments.